Solid Biofuels

Imagine a fuel with the same energy, density and material handling properties of coal, without the associated carbon footprint, heavy metal or sulfur content. The University of Minnesota's Natural Resources Research Institute (NRRI), a leader in the efficient processing of cellulosic biomaterial into carbon neutral biocoal, has engineered such a fuel. Known as torrefied biomass (or biocoal), the fuel conversion process is a derivative of coffee roasting technology originally designed in the early 20th century in France (torrefaction = "to roast" in French).

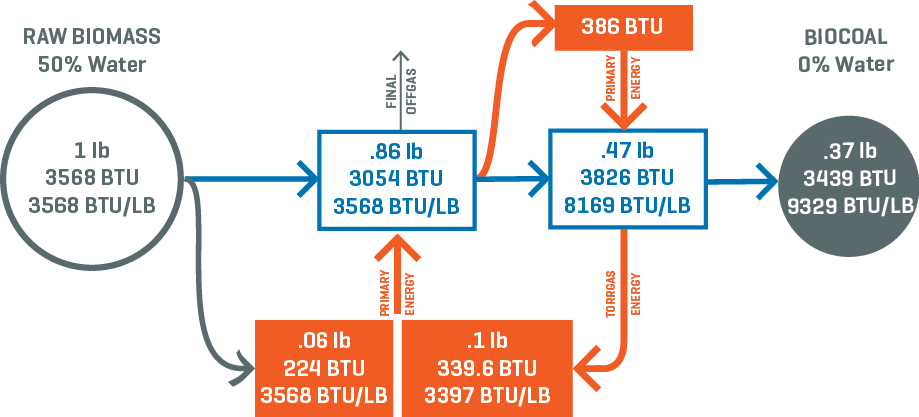

This is not coffee roasting technology anymore. Raw biomass is heated up in a sealed, oxygenless environment to between 250 and 300 degrees Celsius, a process known as partial pyrolysis. At this temperature, many of the volatiles in the woody biomass begin to decompose and part of the sappy lignin that binds the material together breaks down and vaporizes. This gas is captured in the sealed vessel, then returned to the original heat source to add to the combustion heat and increase the thermal efficiency of the reaction system. Research has shown that the fuel conversion process is up to 96% thermally efficient.

Once torrefied, the biocoal is densified at a specific temperature and, thanks to the remaining lignin in the wood, requires no binding agent to maintain its form, which can be pellets, briquettes, bricks or any other shape, as requested by the end user.

Why torrefaction?

Solid biomass, be it agricultural or forest product, is a readily-available, easily renewable fuel source that is easier and more efficient to combust and refine than liquid biofuels. That said, in its raw form, biomass has many attributes that make large-scale economic utilization difficult: its low density, high variability in energy content and the fact it absorbs water (hydrophilic) and will rot / offgas carbon monoxide. The largest biomass export and utilization companies in the U.S. require large bunkers to keep the material dry, and they need to deal with combustible, poisonous carbon monoxide which, when contained in a sealed space, can be concentrated to a level that is fatal to humans.

Raw biomass is heterogenous in nature and difficult to manage. When torrefied, however, it becomes homoginized, not to mention additional value added characteristics.

NRRI is currently concentrating its efforts on the categorization and torrefaction of forest products, including its hybrid poplar tree population, a tree which grows to 50 or 60 feet in seven years. The raw poplar wood is roughly 6,500 btu/lb dry, contains a mix of volatiles, absorbs water, is difficult to grind and is relatively cumbersome to transport. When torrefied, the energy density of the material increases to roughly 10,500 btu/lb, it no longer contains the mix of volatiles, it does not absorb water (hydrophobic), it is equally easy to grind as carbon coal and is very easy to transport, and the material only loses about 15% of its calorific value while being 96% thermally efficient to produce. It is, in fact, more energy efficient to torrefy certain biomaterials than it is to mechanically dry them in wood chip production.

What started as wood is transformed into a coal-like biofuel that features none of the heavy metals, sulfur, phosphorus or net carbon emissions of coal. The feed stock is also carbon-neutral, having sequestered carbon as it grew and, so long as the forest stock is sustainably managed, something in which the University of Minnesota - Duluth is a leader, will remain a carbon-neutral fuel source.

Due to the abundance of sustainable forest in Minnesota and the energy efficiency of the torrefaction process, biocoal can be produced at reasonable cost. Though not as cheap as current domestic coal production, this price range is significantly lower than the diesel fuel that currently powers all diesel-electric fleet. When comparing the fuels on a one-to-one scale, factoring in the overall thermal efficiency of each technology, the efficient external combustion of biocoal makes it substantially less expensive than diesel fuel.

This project will not only provide economic benefit to Minnesota through the employment of wood harvesters and researchers, but will also be a step towards developing U.S. energy independence with a truly renewable fuel.

Torrefaction

Torrefied biomass is regarded as one of the most efficient biofuel manufacturing processes available today. By recycling excess gas produced during the torrefaction reaction to optimize the manufacturing process, researchers at NRRI are able to achieve up-to 96% thermal efficiency in its production. As a point of comparison, the thermal efficiency of charcoal production is 20-40% and the production of bio-diesel and soy-diesel is often close to zero.

Mass Energy Balance of Drying Wood

CSR, in partnership with the U of M and its research partners, is working towards funding the final push of research to make large-scale biocoal manufacture a reality. By developing a medium-scale biocoal production facility in Minnesota, NRRI will be able to produce a steady supply of biocoal to power CSR's steam locomotive, and will also begin to fuel the steam plants in the region on a test basis.

MASS ENERGY BALANCE OF TORREFYING WOOD

Current research is focusing on the development of an integrated torrefaction reactor and small-scale, distributed generation power plants. The benefit of easy-to-operate, easy-to-maintain steam-based electrical generation is an opportunity that has been all-but overlooked that, when combined with a fuel homogenization system like torrefaction, can generate significant benefit in both the U.S. and overseas.

This 28,000 pound-per-day torrefaction reactor is being installed and commissioned at NRRI's Coleraine Minerals Research Laboratory in Coleraine, Minnesota.

The torrefaction of pest plants, such as kudzu in North America and water hyacinth in Africa, can create a fuel product capable of easily powering generators on a distributed basis, or large-scale power facilities. CSR provided NRRI with kudzu in early 2011 for torrefaction, producing promising results. What began as RAW KUDZU with 6.8% moisture and 7,802 BTU/lb became TORREFIED KUDZU with 0% moisture and 9,868 btu/lb, a 21% increase in energy density and a fuel with greater energy density than the most-used coal in the U.S.

Characteristics of solid fuels compared to Torrefied biomass

| Characteristic | Wood | Wood Pellets | Torrefied Biomass | Charcoal | Coal |

|---|---|---|---|---|---|

| Moisture Content (% wt) | 30-40 | 7-10 | 1-5 | 1-5 | 10-15 |

| Calorific Value (BTu/lb) | 3,850-5,100 | 6,450-6,850 | 8,600-11,000 | 8,000-9,500 | 8,600-14,000 |

| Volatiles (% db) | 70-75 | 70-75 | 55-65 | 10-12 | 15-30 |

| Fixed Carbon (% db) | 20-25 | 20-25 | 28-35 | 85-87 | 50-55 |

| Bulk Density (lb/cu.ft.) | 12.5-15.6 | 34.3-46.8 | 46.8-53.1 | 12.5 | 49.9-53.1 |

| Vol/ Density (BTU/cu.ft.) | 53.7-80.5 | 201.3-279.1 | 402.6-501.9 | 161.0-171.8 | 493.8-638.8 |

| Dust Levels | Average | Limited | Limited | High | Limited |

| Hydroscopic Properties | Hydrophilic | Hydrophilic | Hydrophobic | Hydrophobic | Hyrdrophobic |

| Biological Degredation | Yes | Yes | No | No | No |

| Milling Requirements | Special | Special | Classic | Classic | Classic |

| Handling Properties | Special | Special | Classic | Classic | Classic |

| Product Consistency | Limited | High | High | High | High |

| Transportation Cost | High | Average | Low | Average | Low |