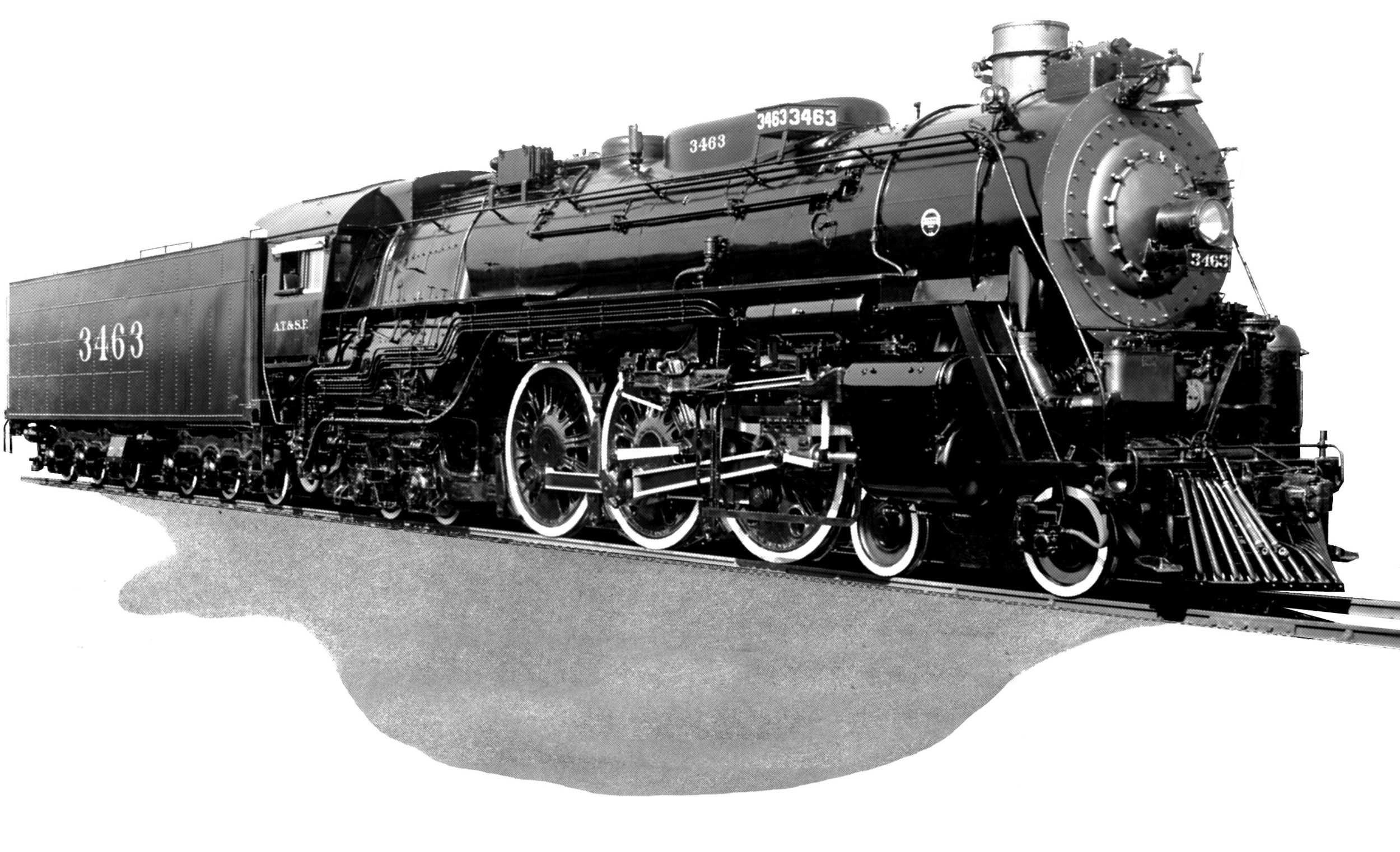

Milwaukee County Zoo train on a trial - the first locomotive is burning 100% torrefied biomass, and the trailing locomotive is burning a 50/50 blend of torrefied biomass and coal.

Two steam locomotives at the Milwaukee County Zoo were fueled with a renewable wood-based solid fuel last week to reduce fossil coal emissions, and the tests were a success.

The Coalition for Sustainable Rail (CSR) and the Natural Resources Research Institute (NRRI) completed a final series of three biofuel trials following more than a year and a half of development of the fuel at NRRI’s Renewable Energy Lab in Coleraine, Minn. Thanks to the generosity of the Milwaukee County Zoo, its small 15-inch gauge railroad has served as a demonstration platform for CSR and NRRI to see how a wood-based torrefied biomass fuel product burns in locomotive-style boilers. Tests in June and October 2016 revealed that the biofuel could make sufficient steam, but improper pelletizing methods resulted in spark emissions from the locomotive.

“Following the first trials, our researchers set about devising a better method to densify the material, including acquiring an industrial scale densification machine that we installed at our lab in Coleraine,” explained NRRI Associate Director, and CSR Board Member, Don Fosnacht, Ph.D. “Combined with a food-grade binding agent, we were able to make dense, pill-shaped pellets for use with these Zoo test trials that burned exactly like coal.”

No. 1924 hauls the test train up the steepest grade on the Zoo railroad burning 100% torrefied biomass.

NRRI is currently researching the opportunities in “torrefied biomass,” a wood-based biofuel that is made in a kiln not unlike a coffee roaster. After being “roasted,” the wood is transformed into a fuel that burns and reacts much like coal, with virtually no heavy metal pollutants and reduced carbon emissions. NRRI provided three blends of torrefied biomass to the Zoo for testing: 1) a blend of 99 percent torrefied biomass and 1 percent binder agent; 2) a blend of 49.5 percent torrefied biomass, 49.5 percent Powder River Basin coal, and 1 percent binder; and 3) a 100 percent torrefied biomass pellet with no binder. Each of the fuels was tested in the Zoo train locomotives, and two were found to be ideal stand-in fuels for fossil coal.

Pre-blended torrefied biomass / Powder River Basin fuel pellets ready to load in the tender of No. 1924.

“The torrefied biomass with binder, and the 50/50 blend of coal and biofuel, worked quite well in both locomotives,” said CSR President Davidson Ward. “Both fuels burned nearly identical to coal, including building a decent coal bed on the grates and maintaining pressure under a wide variety of operational circumstances, while being nearly smoke and odor free.”

Initial temperature data also indicate that the biofuel heating value is equal to coal. The maximum firebox temperatures recorded during the biofuel trials were in excess of 2,100 degrees Fahrenheit (1149 Degrees Celcius).

“I am quite impressed with what I saw from this round of biofuel testing, and I look forward to burning it in our steam locomotive,” said Zach Hall, Steam Operations manager at the Everett Railroad, who was on site to participate in the tests. “From my observations, both the biomass with binder and 50/50 blend of fuel will do just fine to make steam and minimize smoke, both of which are good things in my book.”

CSR and NRRI are ramping up for the next round of tests: manufacturing 10 tons of fuel for use by Everett Railroad steam locomotive No. 11 early next year. In support of these tests, CSR is undergoing a matching grant fundraising process, whereby donations to the non-profit made between now and December 15 will be matched dollar-for-dollar (up to $10,000).