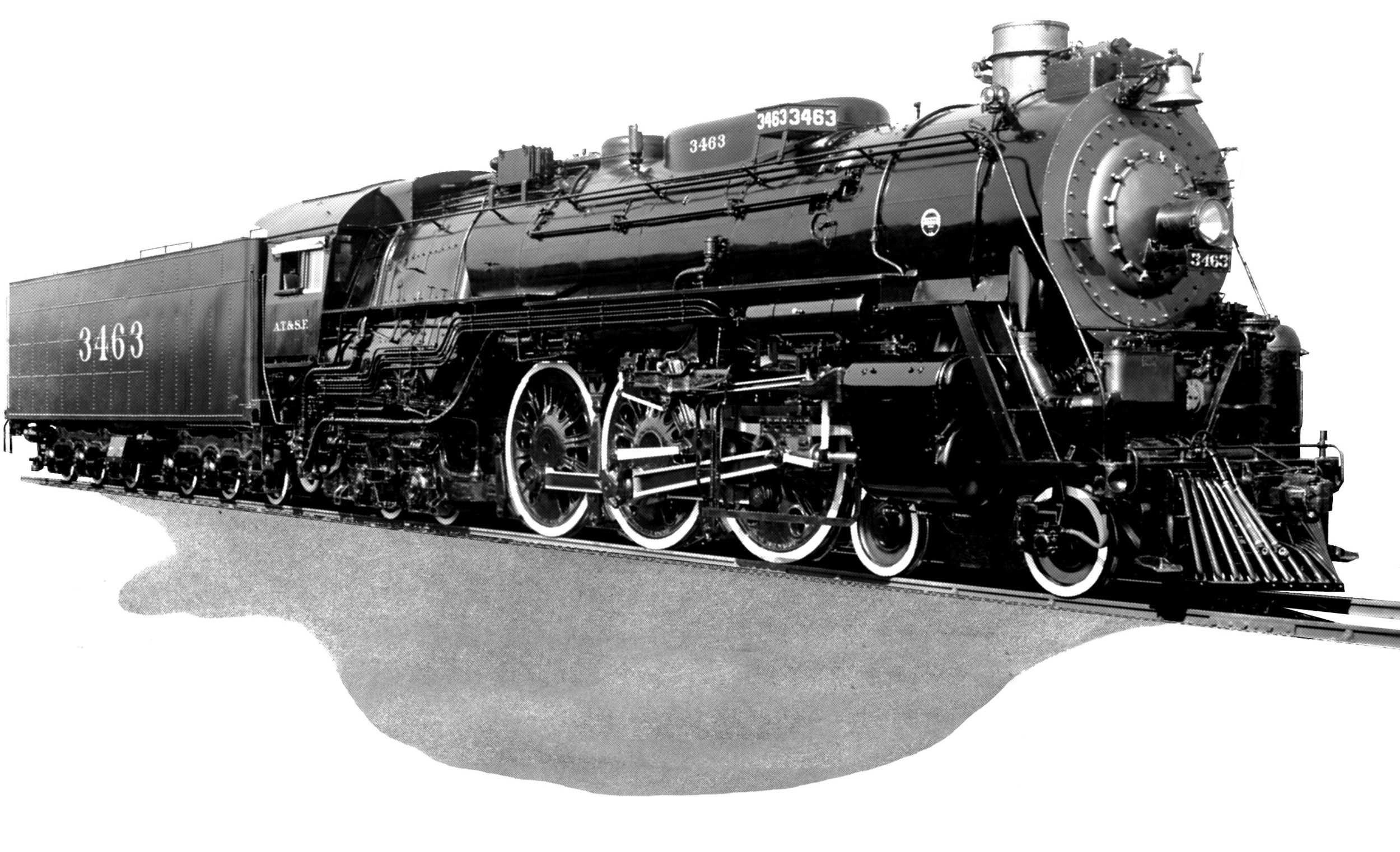

T O P E K A, K A N S A S | April 11, 2017 – Shawnee County District Court has ruled in favor of Sustainable Rail International d/b/a Coalition for Sustainable Rail (CSR) in its case concerning quiet title of the former Atchison, Topeka & Santa Fe Railway (ATSF) steam locomotive No. 3463. District Court Judge, the Honorable Larry D. Hendricks, released a detailed decision concerning the case Wednesday, March 29, 2017, in which he finds that defendant Topeka Children and Santa Fe Railroad, Inc. (TCSFR) has no standing to remain in the lawsuit. This decision paves the way for CSR to enter negotiations with the City of Topeka concerning the locomotive.

“Now that the court has determined that TCSFR does not have sufficient standing to remain in the lawsuit, we look forward to working with the City of Topeka to resolve the matter,” said CSR President Davidson Ward. “Of specific importance to CSR is outlining a realistic path forward that provides for the preservation of No. 3463 and a secure facility in Topeka for it to call home.”

CSR’s ownership of No. 3463 was first challenged by the TCSFR in April 2013 who, at that time, claimed absolute ownership of the locomotive. Following months of unsuccessful attempts to meet with TCSFR about its claims, CSR filed suit in May 2014 requesting a legal determination as to ownership of No. 3463. Shortly after filing suit, TCSFR reversed its position of outright ownership, claiming instead that they were trustees of a trust to protect the locomotive, and that the City of Topeka was the rightful owner, thus drawing the City into the suit as a Party Defendant.

“Through his decision, Judge Hendricks plainly sets forth why each of TCSFR’s arguments fails as a matter of law. While we were confident in our position, the decision clearly supports CSR and the filing of this litigation,” said outside counsel to CSR Matthew Bergmann, of Topeka-based Frieden, Unrein and Forbes, LLP. “We are extremely pleased with Judge Hendricks ruling.”

“Of specific importance to CSR is outlining a realistic path forward that provides for the preservation of No. 3463 and a secure facility in Topeka for it to call home.”

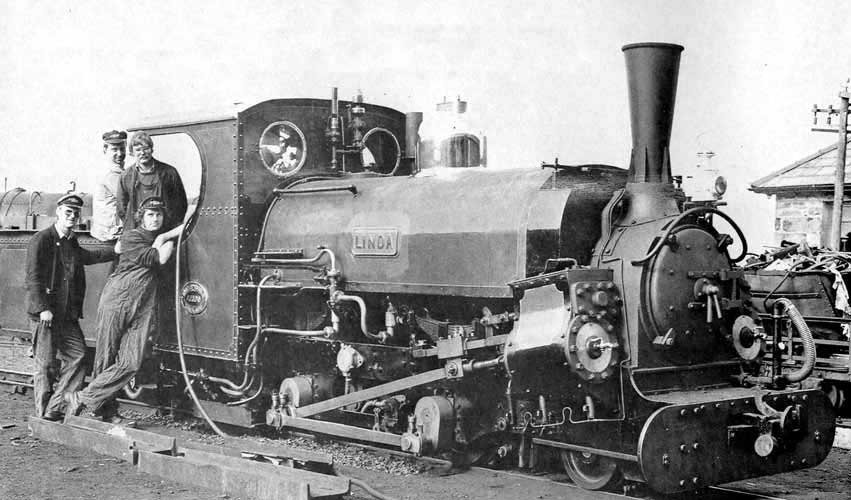

Though the project with No. 3463 has been on hold since 2013, CSR has worked diligently to refine its focus in both the preservation field and the steam and biofuel arenas in response to changing market conditions. Not only has the organization been retained to assist railroads in Germany and the U.S. with matters concerning steam locomotive preservation, but it has also been working with research collaborators at the University of Minnesota to further advance fuel and boiler technologies.