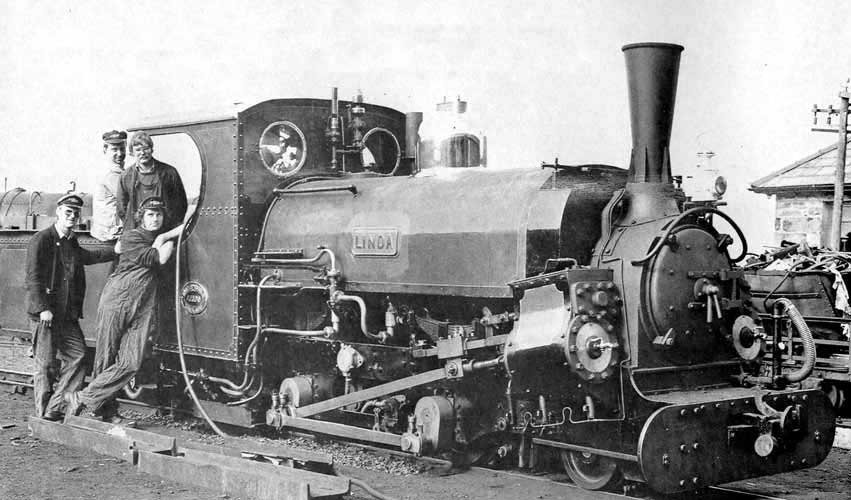

Milwaukee County Zoo locomotive number 1924 served as the "guinea pig" on these first torrefied biomass tests. Operating on 15 inch gauge track, the locomotive is the perfect scale to begin combustion analyses of torrefied fuel under the highly variable drafting of steam locomotive boilers.

From June 10-12, CSR teamed up with the Milwaukee County Zoo, the Natural Resources Research Institute, and New Biomass Energy to undertake the first test of torrefied biomass on a steam locomotive. The tests are a key step in ensuring that the fuel can be used in steam locomotives of all sizes in the face of shuttering coal mines.

Torrefied biomass pellets used in the testing.

The Milwaukee County Zoo operates two steam locomotives on its 15 inch gauge railroad. With just over a mile of mainline track and upwards of 30 trains per day, the Zoo operation provided CSR the opportunity to compare runs burning coal with identical runs burning "torrefied biomass," also known as "biocoal," in a controlled, test-scale environment.

"We instrumented the locomotive with four, Inconel-sheathed thermocouples to gauge firebed, combustion space, and exhaust gas temperatures when burning coal vs biocoal," explained CSR Senior Mechanical Engineer Wolf Fengler. "Tests were run on Saturday and Sunday, with trains Saturday burning coal and the first runs of Sunday burning biocoal."

Modified grates [bottom] and two of the three thermocouples poking through staybolt telltale holes [left]. Click to Enlarge

CSR worked hand-in-hand with Zoo staff to instrument 4-6-2 steam locomotive number 1924 and undertake the tests [see diagram below]. Torrefied biomass fuel was graciously donated by New Biomass Energy for use during research. The small fuel pellets were burned on a modified stainless steel grate installed by CSR on-site.

"We used National Instruments hardware in concert with its LabView software to record second-by-second temperature data from the sensors," said CSR President Davidson Ward. "Perhaps most exciting was the fact that three of the sensors were directly in the firebox, one submerged in the firebed and two at varying heights above, each of which provided better insights into the combustion behaviors of each fuel."

[Click to Enlarge]

While data processing is still underway, initial results indicate that the torrefied biomass fuel burns with a very similar temperature profile as the coal used by the Zoo, but the biomass had a much longer flame profile, which bodes well for producing more uniform stresses in the firebox.

The video below shows a comparison of coal with biocoal under identical, hostling circumstances. Note the length of flame and brightness of the fire generated by the torrefied biomass.

More information, including additional videos of the tests and a detailed White Paper, will be made available later this summer. CSR plans to undertake a second set of tests with the Milwaukee County Zoo with larger torrefied biomass pellets created by NRRI at its Coleraine Minerals Research Laboratory later this year. The organization has also been in discussions with standard-gauge operators about undertaking full scale tests in the future.

The Milwaukee Zoo train tests were made possible by the outstanding assistance of the Milwaukee County Zoo, the Natural Resources Research Institute, New Biomass Energy, the American Boiler Manufacturers Association, and the support of CSR's donors, including generous contributions by Bon French and Fred Gullette.

If you have yet to do so, please:

Dedicated to: Randy Rawson

For the duration of biofuel testing, CSR renamed locomotive 1924 "Randy Rawson" in honor of the former President of the American Boiler Manufacturers Association, W. Randall Rawson, who died in November 2013. He was a superb friend and advocate of CSR, having expressed unwavering interest and support of our biofuel and steam locomotive research. He had always wanted to be present for the first tests of torrefied biomass in a steam locomotive, and we wanted to do our part to honor him. To this day, Rawson's legacy, sense of humor, and enthusiasm continue to serve as an inspiration to the leaders of CSR.