“Lastly, of course there are the locomotives themselves, magnificent machines that were the true inspiration”

Girdlestone shows off a newly-manufactured lightweight multi-ring piston valve from an ACR NGG16. Photo: ACR

Within the past decade, the last revenue-earning steam locomotives have almost entirely vanished from the Earth. While there are thousands parked in municipal parks and museums, the few that remain in operation today are primarily for the tourist-hauling public – a reminder of the trains of yesteryear.

However, a small group of dedicated mechanical engineers and steam technicians have spent years working to make the steam locomotive as mechanically and thermodynamically efficient and reliable as possible. Three of the leading experts, David Wardale, Shaun McMahon, and Phil Girdlstone, are disciples of Argentinean modern steam locomotive expert Livio Dante Porta. Each of them worked directly with Porta on a number of projects on five continents, and following Porta’s death in 2003, they were left to carry on his legacy. One of the most accomplished and senior members of that group, Phil Girdlestone, has died this week at the age of 61.

Phil Girdlestone (1954-2016) was born in London and, like many children, he became fascinated with the steam locomotive. He spent many hours as a child watching the mainline steam locomotives of the British Railways chuff by, and he also witnessed their replacement by the diesels and electric locomotives that rule the rails today. Girdlestone believed that the steam locomotive still held promise but in a more refined form. In the words of Bob Harris, former Assistant Works Manager at the Ffestiniog Railways Boston Lodge Works: “Phil is a man who firmly believes in his own vision of steam locomotives, born twenty years too late!”

Girdlestone started his railway carreer on the 1`-11 ½`` gauge Ffestiniog Railway in north Wales in the summer of 1970 as a volunteer fireman at the age of only 15. By 1977, he had qualified as one of the very few (in those days) volunteer drivers on the line. In January 1979, Girdlestone joined the permanent staff at FR's Boston Lodge Works, and he was soon appointed to the position of Technical Assistant. This allowed him to develop the steam locomotive fleet so as to incorporate modern cost effective enhancements. Brought up in the Allan Garraway-era of the FR, Phil was a keen and disciplined engineer, and he always insisted upon the highest standards when out on the mainline.

This 1984 photograph of the Boston Lodge Workshop shows a 30 year-old Girdlestone (center with paper in hand) as well a 19 year-old McMahon (second from right in the back row). Photo: collection of S.T. McMahon

In the 1982, Girdlestone began correspondence with David Wardale and L.D. Porta regarding modern steam development work in South Africa and Argentina. By 1981, the advanced steam improvements to a South African Railway Class 25NC 4-8-4 number 3450 (nicknamed “Red Devil” due to its paint scheme) began to make news. Wardale and Porta had engineered and rebuilt the locomotive to include the latest in thermodynamics, resulting in a steam locomotive that was more powerful, cheaper to maintain, and cheaper to operate than all diesel-electric locomotives on the railroad. In raw numbers, the narrow-gauge 4-8-4 generated more than 4,400 drawbar horsepower (43% higher than standard 25NCs), could travel faster than 75 mph with a 22 car passenger train, and saved 30% in coal and water compared to the unmodified locomotives.

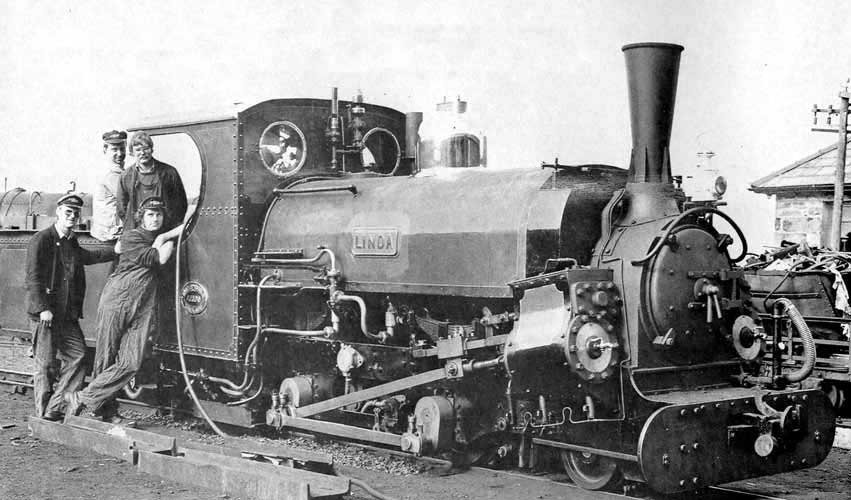

The evidence of modern steam application was staggering, and Girdlestone sought to bring modern steam to his native Great Britain. By 1983, he had been appointed Works Superintendent at Boston Lodge, and he began applying a much heavier set of improvements to 2-4-0 saddle tank tender locomotive (STT) No. 590, a Hunslet Engine Company-manufactured steam locomotive built in 1893. He and his crew, including a young Shaun McMahon, converted the 2-4-0STT named “Linda” from oil to coal with an advanced “Gas Producer Combustion System” and Lempor exhaust, much of the same improvements made to the “Red Devil.” After initiation into service in 1985, Linda quickly proved its worth, able to haul longer trains than in its previous configuration as an oil burner, with less than 70% the operating cost of an oil-burning locomotive. Ultimately, a significant drop in oil prices in 1986 resulted in the engine being re-converted to oil, making again a homogenous fleet at the Railway.

Girdlestone (forefront in the cab) with "Linda" post conversion on the Ffestiniog Railway. Note the new smokestack with reinforced gussets along narrow portion. Photo: G. Rushton, collection of S.T. McMahon

The work at the Ffestiniog Railway a technological success, Girdlestone moved to live and work in South Wales at Hugh Philips Engineering Ltd. and worked on the Sudan locomotive modernization program, which included modernization of the locomotive fleet by applying Lempor exhausts and a modified rotary oil burner. Prior to this, Phil had been on standby to move to the U.S to take the position of chief draughtsman on the ACE 3000 project alongside Porta and Wardale. To that end, Porta often described Phil as “the best draughtsman he had ever come across in all of his working years.”

During the summer of 1988, Girdlestone was contracted for a three month period by the Brecon Mountain Railway to design new boilers for their existing fleet as well as consult on the forthcoming purchase of the Vale of Rheidol Railway in mid-Wales by the same company.

Also in 1988, the then-recently-privatized Alfred County Railway in South Africa had begun steam-hauled freight service. The two-foot-gauge ACR hauled logs, produce, and some passengers over its 75 mile-long railroad. The line used a fleet of NGG16 Class 2-6-2+2-6-2 Garratt locomotives to haul its trains, and management, aware of the successes of the “Red Devil” and work Girdlestone had undertaken in Great Britain and Sudan, hired him to serve as its fulltime Chief Mechanical Officer.

Moving from Great Britain to South Africa in September 1988, Girdlestone immediately began modernization work on locomotive 141. The 40 foot long, 62 ton locomotive was significantly larger than “Linda,” carrying a boiler pressure of 180 PSI and generating 21,360 lbs of tractive effort, complete with superheat. Girdlestone and his crew rebuilt the locomotive with a GPCS, Lempor exhaust system, self-cleaning US-style Master Mechanics’ smokebox, computer-designed light weight piston valves with multiple rings (to save steam consumption), and additional improvements.

Girdlestone (middle with arms crossed) and the shop crews at ACR stand before locomotive 138 in February 1996. Photo: collection of S.T. McMahon

Reclassified as NGG 16A, locomotive No. 141 rolled out of the shop in a bright red paint scheme in August 1989, and it showed immediate improvements (it too was soon nicknamed - based on its coloration –as the “Red Dragon.”) The rebuilt locomotive saved more than 30 percent on coal, generated 10 percent increased pulling power, and significant maintenance cost savings. The modifications to the Red Dragon resulted in 90% availability, and the cost of the improvements was paid off in less than 12 months. A similar rebuilding of ACR No. 155 was undertaken in 1990, resulting in equally impressive results. In addition to developing the NGG 16A class locomotive, Girdlestone went on to design both the NGG 16B and NGG 17 class locomotives for use on the ACR and other South African two foot gauge railways on the national system.

Girdlestone leans out the cab of ACR 141 as it powers up Wilson's Cut. Note the lack of smoke from the stack. Photo: ACR

While at the ACR, Girdlestone hired Porta disciple Shaun T. McMahon as Assistant CMO of the railroad. Girdlestone hired McMahon to assist during a time of ACR business and the planned takeover of the Port Elizabeth branch. This provided McMahon an opportunity to gain significant experience hands on in the advancement of steam technology.

While at ACR, Girdlestone was co-opted on to a committee to determine what fuel options were open for a partial retention of steam on the 3'-6" gauge SAR mainline (soon to be converted into semi-privatized Spoornet). At that time, steam was still in service only between Kimberley and De Aar and in switching services on the Reef. The result of this initiative was the first oil-fired SAR steam locomotive since an experiment in 1946. This was 15F class 4-8-2 No.2916 which was converted at Germiston depot using equipment from East African Railways, and Girdlestone was brought in to help supervise the tests and tuning up.

This 1991 photograph shows Girdlestone (second from left) shown with other crew involved with conversion of SAR 15F Class 4-8-2 No. 2916 from coal to oil firing. Photo: P. Girdlestone courtesy of H. Odom

The application of the East African "American-type" trough burners to No.2916 was not particularly successful and Girdlestone suggested an alternative. As a result he was asked to design equipment for the conversion of a 25NC class 4-8-4. The impetus behind all this work was to equip locomotives for work during the dry season, the formation of Spoornet having seen elimination of steam in normal service. It was now operated on behalf of the Transnet Heritage Foundation and normal line clearing and the making of firebreaks had ceased. The new burners were circular with superior atomising characteristics and the first was applied to a 25NC of Beaconsfield depot at Kimberly. It was subsequently applied to a second 25NC No.3417 and retrospectively to 15F No.2916 with success.

Girdlestone remained at the ACR through 1999, some years before the railroad shut down operations due to increased truck freight competition, issues with the national railroad board “Spoornet,” and the washing away of a large rail bridge in a flash flood.

West Coast Railway Class R 4-6-4s numbers 711 and 766 undertake a light engine move from Ballarat to Newport on May 11, 2004. Photo: Tony 'Ashcat' Marsden

In 1996 , Girdlestone opened “Girdlestone and Associates,” which undertook contract advanced steam engineering and retrofitting work across the globe.The first major project for G&A took place with the modernization of West Coast Railway (Australia) Class R 4-6-4 type locomotives numbers R 711& R 766, for which Girdlestone provided detailed engineering drawings via correspondence. The retrofits included application of a dual Lempor exhaust, conversion from coal to advanced oil firing, addition of power reverse, and additional detailed improvements to allow the locomotives to maintain speeds on regular steam-hauled excursions between Melbourne and Warrnambool, maintaining a 3 hour and 13 minute schedule along the 166 mile route. The WCR reported a 30% improvement in power and a 30% reduction in fuel consumption compared with standard R class 4-6-4s.

From 2003, Girdlestone (second from right) stands with some of his crew members beside the two foot gauge Class LSN he was building from scratch for a customer in the UK. Photo: collection of S.T. McMahon

Between 2000 and 2003 G&A designed and manufactured the main bulk of a two foot gauge modern steam locomotive for a UK customer, denominated Class LSN. The firm was also hired by Spanish based company ARMF for a number of years so as to carry out locomotive modification work.

Girdlestone stands in front of P36.0032 after installation of the dual Lempor. Photo: Collection of P. Girdlestone

Following the engineering work in Australia, Girdlestone took on work modernizing a broad-gauge Russian P36 Class 4-8-4 number P36.0032. The locomotive is owned and operated by Golden Eagle Luxury Trains, a company that operates luxury passenger trains in Russia. They hired G&A to design and construct an advanced dual Lempor Exhaust system for the large passenger locomotive. The one-ton assembly was manufactured in South Africa and air-freighted to Saint Petersburg, Russia, where it was installed on the locomotive in 2004. The train operator realized significant power improvements post-installation, and the locomotive maintains the exhaust system today.

Around the same time, G&A was hired by Argentina’s Ferrocarril Austral Fueguino, a 500 mm gauge operation that hauls tourists in the southern-most city of Ushuaia in Tierra del Fuego. G&A built an 0-6-0 diesel hydraulic locomotive based on a UK design and, later on during 2005, built an 0-4-0+0-4-0T Garratt locomotive from a mix of spare components left over from a spare Garratt that was never completed and a range of new major components, including a new boiler. The small locomotive included the utmost in modernizations and went into service in 2006. It has operated with diesel-like availability and cheaper-than-diesel maintenance and fuel costs since entering operation.

FCAF locomotive "H.R. Zubieta" on a revenue train. The locomotive was built from scratch by G&A in South Africa and shipped to Argentina in 2006. Photo: FCAF

Up until his death, Girdlestone had been focusing on authorship, including having recently published a book detailing the history of SAR Class 25 Condensing and Non-Condensing 4-8-4s (Camels and Cadillacs, Stenvalls 2014 – ISBN 978-91-7266-185-1). He also had a hand in multiple projects advancing the state of the art in steam technology. It is worth noting that his autobiography is complete and awaiting publication.

Girdlestone was dedicated to steam technology, traveling the world in pursuit of its advancements pushing the state of the art. It was his passion for technology, science, railway development and, above all, the steam locomotive, which drove Phil Girdlestone to dedicate so much to the iron horse.

Phillip R. Girdlestone, locomotive engineer, born September 1, 1954; died April 20, 2016