Everett Railroad No. 11 hauls revenue freight with torrefied biomass in December 2021. Thanks to Joseph Carter and the U.S. Endowment for Forestry and Communities for the photograph.

Since our last posting, CSR has been making steady progress on its key initiatives. Perhaps most importantly, however, CSR leadership have been working to develop a plan to manage its transition and future. This process has involved substantial discussion and planning at an organizational level.

Biofuel Research

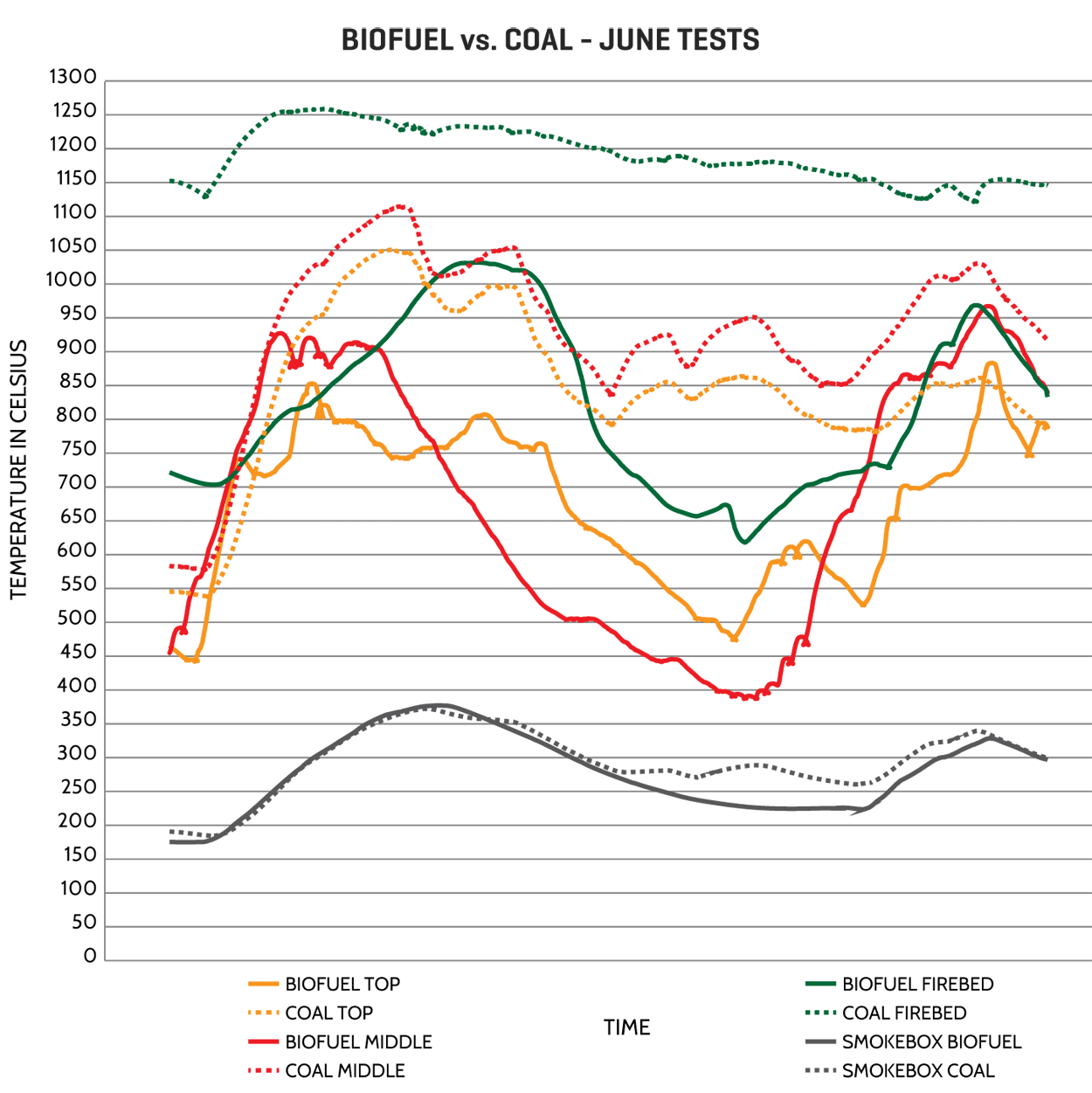

Since the onset of the pandemic, the Natural Resources Research Institute, our primary biofuel collaborator, has announced a shift in its research focus away from woody fuels stocks and into higher value biomass research (NRRI Article here). That said, we have begun a working relationship with another supplier of biofuel to advance trials in torrefied biomass fuels in steam locomotives, most recently operating a series of trials at the Everett Railroad in December 2021. In fact, some of the last solid fuel burned in Everett Railroad steam locomotive No. 11’s firebox, prior to its conversion to oil, was our torrefied biomass

We are currently working with a few steam operators to take the lessons learned from the Everett Railroad trials to develop enhanced blends of fuels for additional trials. We are happy to note, however, that additional fuels providers across the globe are beginning to supply and trial torrefied biomass fuels for use in steam locomotives, particularly in Europe. Issues associated with coal supplies have hit the UK heritage railways particulary hard, and we are honored to have a chance to assist a few operators in pursuing newer technologies.

As referenced in the NRRI Article above:

NRRI pursued this research with an industry partner, Gradient Technologies, to scale up a novel, steam-based moving bed technology to make the bio-based solid fuel. The technology was tested with a small batch reactor at Gradient Technologies in Elk River, Minn., in 2014, then scaled-up four times larger at NRRI’s Biomass Conversion Lab in Coleraine, Minn.

The 35-foot-tall moving bed torrefaction system was funded with a renewable fuels grant from Xcel Energy. The reactor was designed to thermally treat up to three tons of biomass a day on a continuous basis as an industrial-scale demonstration. The fuel would burn in a unique boiler designed by the Coalition for Sustainable Rail to produce both steam and electricity.

But the [fuels] process didn’t work as planned, the market drivers changed and NRRI researchers knew it was time to pivot to other opportunities, like biochar and other carbon products. The team is looking into new funding sources to further develop these opportunities.

The biofuel boiler, designed by CSR and manufactured by Williams and Davis Boilers, was a novel 300 PSI firetube boiler that was to be coupled with a Practical Steam Engine rotary engine to generate 100 kWe. Though the project was cancelled in late 2021, NRRI and CSR are pursuing other opportunities to test and use the boiler generator system. Pics of the system being delivered to NRRI are shown below.

Santa FE 3463

A group of dedicated volunteers in Topeka, Kansas, continues to make progress on the cosmetic stabilization of No. 3463. As is outlined on our page about the locomotive, the goals of the organization regarding No. 3463 are focused on preserving it in place and developing a long term means to preserve the artifact.

Due to a five year delay stemming from a challenge to CSR’s ownership of the locomotive (the challenger was eventually removed from the lawsuit), forward progress with No. 3463 and its restoration was all but halted from 2013 until 2018. Quoting Wolf Fengler from 2018:

Instead of hoping and waiting for the lawsuit to be resolved in our favor, we decided to continue our pursuit of solid biofuel, steam locomotive, and advanced steam technologies. Now that those initiatives are well underway, vetting the theories we had hoped to prove with the Santa Fe locomotive, we have opted to table our plans to modify the engine as a testbed. Instead, CSR will work with collaborators in Topeka to ensure the locomotive is moved, preserved, and, if practical, restored to operation.

CSR is dedicating its resources into preserving No. 3463, supporting grass roots efforts in Kansas to spruce up the locomotive. Some photos of recent work on the locomotive are included below.

The Organization

Perhaps the most important discussions being had internally include: where does CSR go from here? In addition to supporting forward progress on biofuel research, wrapping up the Xcel RDF Grant, and continuing to make progress in preserving No. 3463, the CSR Board is developing a plan for the future of the organization.

It was 2012 when CSR was first launched, and we are proud of the progress that this all volunteer 501c(3) has made. Our research has taken us to Great Britain and Germany, it has supported the development of “Boutique Fuels for Boutique Boilers,” it has seen a test boiler built and delivered, and we have learned innumerable lessons about research, fuels, and steam locomotives.

We aim to announce by midyear a transition plan in the organization regarding our key initiatives. Until then, our volunteers will continue work on No. 3463, supporting biofuel trials, and advancing our mission.