As shown at in the adjacent photo, the cylindrical pellets were relatively easy to crush, a result of the binder used in densification. By comparison, other pellets on hand densified with different binders were nearly impossible to crush, even with a hammer.

Upon the very first fireup, it became apparent that the torrefied biomass fuel burned much cleaner than coal , and that the larger biofuel pellets permitted a thicker firebed with little-to-no visible smoke as compared with the tests in June. Even when stoking the fire with many scoops of torrefied biomass at one time, the smokestack seldom showed more than a translucent gray haze.

On Saturday morning, we arrived early to fire up test locomotive No. 1924 on the torrefied biomass fuel. After about an hour of stoking, the boiler pressure gauge read just shy of 200 psi, and we were ready to begin operating trains.

With Ken Ristow at the throttle, the 4-6-2 gently pulled its train downgrade out of the shop and through the tunnel beneath Interstate Highway 94. With the entire train in the tunnel and at the base of an approximate 3% upgrade, Ristow hauled back on the throttle, agitating the torrefied fire unlike it had yet to experience.

The strong draft, combined with a dormant firebed, resulted in ash and cinders being blasted out of the stack. The engine roared upgrade with its 10 car test train in tow and, once the initial firebed cleaned, the stack went from hazy to clear.

Once at the top of the grade and onto the Zoo mainline, the train stopped to allow crew members to throw the switch. We then began three laps of continuous running to see how the fuel reacted in a “mainline” situation.

With 22” driving wheels and a loop of track approximately one and one-tenth of a mile in length, the tests were undertaken over a “scale” distance of 10 miles of railroad and a top scale speed of approximately 40 miles per hour. With the biofuel tests were completed, we switched the locomotive from torrefied biomass to coal and ran the balance of the normal trains using coal, logging comparative temperature data.

Results

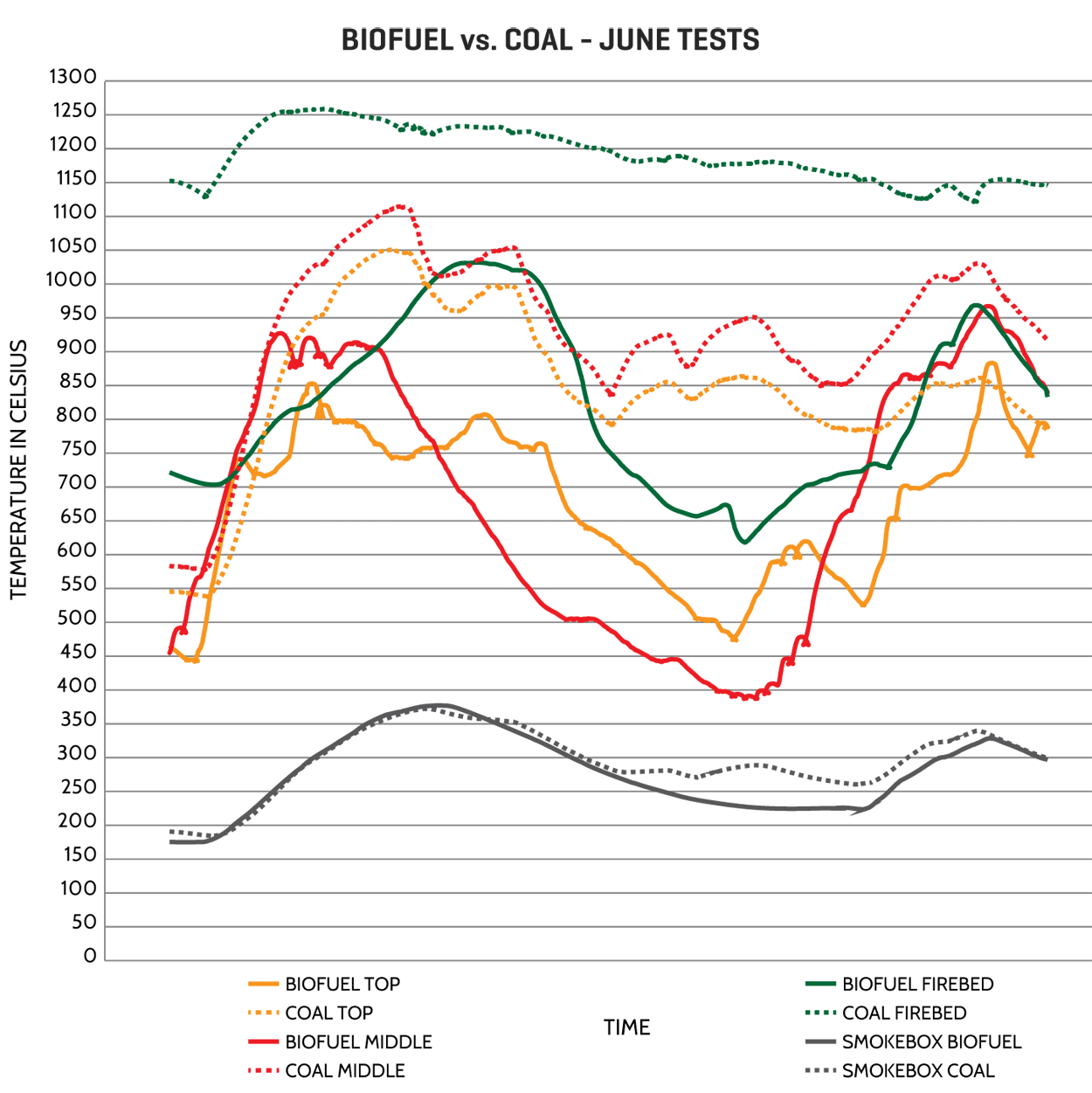

The results of both biocoal/coal comparison tests, one in June with small pellets and one in October with large pellets, are shown below. It is interesting to note the difference in maximum temperatures between the tests, a function most likely of the difference in grates and the impact they had on the coal firebed. Both graphs represent data recorded on two runs and synced them up, shifting the data along the “x-axis” to relate to similar segments of the railroad. Click on the graphs to enlarge.

![Members of the CSR / Zoo research team pose in front of the two steam locomotives operated by the Zoo.• People, from left to right: Davidson Ward [CSR]; Ken Ristow [Zoo]; Rob Mangels [CSR]; and Wolf Fengler [CSR].• Locomotives, from left to right: 4…](https://images.squarespace-cdn.com/content/v1/55e5ef3fe4b0d3b9ddaa5954/1481042813715-4IUMEM6JHWKHEUSFE40J/image-asset.jpeg)